Fabricantes de Tableros de Contrachapados

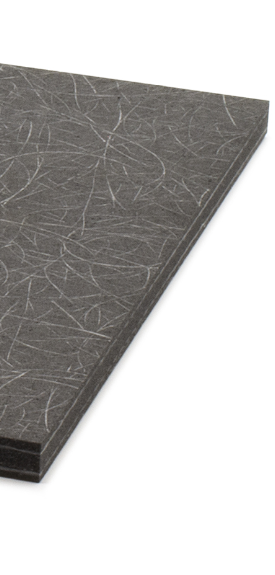

Forest Trafic es la empresa Española Líder en la comercialización de tableros contrachapados de abedul. Estos tableros, provenientes principalmente de Rusia, son desarrollados siguiendo un proceso de fabricación, dónde los troncos humedecidos controladamente, son despalillados, descortazados, y posteriormente desbobinados. La bobina resultante del desarrollo del tronco es cortada en secciones iguales.

Posteriormente estas secciones se encolan (usando resinas fenólicas o ureicas) usando altas temperaturas y presiones, y contraponiendo el sentido de la veta de cada chapa para lograr un panel en el que las fuerzas de cada chapa se contraponen, produciendo así un material duro, estable y más resisten (kilo por kilo) que el acero.

¿Qué son los tableros contrachapados?

Los tableros contrachapados son paneles compuestos por diversas chapas/láminas de madera natural, encoladas y prensadas. Para su construcción, se emplea un número impar de chapas, que son unidas con cola y alta presión, alternando las direcciones de la veta/fibra, es decir, en sentido perpendicular con la anterior y la posterior. Las maderas que más se utilizan en su producción son: Haya, Chopo, Nogal, Fresno, Abedul, Caoba, Pino y Calabó, entre muchas otras.

Los tableros contrachapados que fabrica Forest Trafic tienen tres denominaciones: tablero contrachapado fenólico, tablero contrachapado marino y tablero contrachapado fenólico marino. Para construir este tipo de tableros se utilizan hojas de madera sin agujeros ni huecos de una variedad limitada de especies como puede ser la Caoba o el Abedul y pegamentos especiales basados en fenol-formaldehído o resinas fenólicas de color oscuro que aportan gran resistencia estructural. Su uso es habitual en ambientes exteriores en condiciones de exposición total o parcial a los agentes atmosféricos en una gran variedad de aplicaciones: carpintería, sector naval, carrocerías de vehículos y en la construcción de armarios para cocinas y baños, entre otros. Estos tableros presentan una alta durabilidad, resistencia, estabilidad y facilidad de mecanizado.

Características:

- Resistencia. La resistencia de la madera natural se incrementa al alternarse la dirección de la fibra de las chapas/láminas.

- Ligereza. Esta característica se define por la especie de madera utilizada.

- Estabilidad. Su proceso de fabricación favorece su estabilidad.

- Fácil de trabajar. El formato de tablero facilita su trabajo y mecanizado.

- Aislante y acondicionador acústico.

- Resistente al fuego. La madera y el tratamiento utilizado determinan esta característica.

- Facilidad para el doblado.

- No se cantea.

Tableros Contrachapados

Se obtiene mediante encolado de chapas de madera superpuestas de modo que sus fibras formen un ángulo determinado, generalmente recto. Normalmente están compuestos por chapas impares, con el fin de equilibrar su estructura y comportamiento, y facilitar su curvado. El tablero contrachapado queda caracterizado por la especie o grupo de especies de madera empleadas para sus chapas, la calidad de las chapas y el tipo de encolado. La definición tradicional del tablero contrachapado (formado exclusivamente por chapas de madera) se ha enriquecido con la ampliación a los posibles materiales que se pueden utilizar en su alma. Las denominaciones más habituales son:

Contrachapado de Madera y Plywood de Abedul

Rusia ha desarrollado su competencia como el mayor productor europeo de contrachapado a lo largo de los últimos 100 años. En la actualidad, el contrachapado de madera de abedul procesado finlandés es uno de los productos en tablero derivados de la madera más avanzados para una amplia variedad de exigentes aplicaciones en la industria de la construcción, vehículos y otras industrias especializadas. La otra gran gama importante de productos de tablero contrachapado está basada en el abeto como materia prima.

1.1 LA MADERA, LA MATERIA PRIMA MÁS IMPORTANTE

La materia prima más importante para el tablero contrachapado es un recurso natural renovable,la madera. El plywood de abedul (Betula pendula, hardwood) y el abeto (Picea abies,

softwood) son las materias primas más importantes en el proceso del contrachapado.

Los árboles crecen despacio en el clima de Finlandia y, por ello, la madera que producen

es compacta y de una alta calidad constante.

El abedul es de una consistencia uniforme y tiene unas excelente propiedades de resistencia, desenrollado y encolado. El abeto es una especie de madera menos densa y más

económica para el contrachapado de abeto en su totalidad y en construcciones especiales de chapas de abedul y abeto combinadas.

1.2 ENCOLADO

La amplia mayoría del contrachapado finlandés es de construcción de veta entreruzada

encolada con un adhesivo de resina fenólica. La calidad de encolado normal es adecuada para su uso en exteriores (clase de servicio 3) cuando esté adecuadamente protegida. Una pequeña parte de la producción de contrachapado finlandés de veta entrecruzada

está encolado con cola de formaldehído de urea. Estos paneles son adecuados para su

uso en ambientes secos (clase de servicio 1) o húmedos (clase de servicio 2).

El encolado con fenol-formaldehído cumple los requisitos de la EN 314-2 clase 3 para

exteriores. La calidad del encolado puede aún remitirse a una anterior clasificación nacional como DIN 68705, BFU 100 o BS 6566: WBP.

Los productos de contrachapado finlandés encolados con fenol-formaldehído muestran

bajos niveles de emisiones de formaldehído. Los productos encolados con ureaformaldehído tienen valores ligeramente más altos, pero aún así cumplen los requisitos

de las normas europeas más exigentes relativas a la emisión y contenido de formaldehído.

Tablero contrachapado multicapa: está integrado por más de 3 chapas.

Tablero contrachapado con alma: cuando incluye un alma que no es una chapa de madera.

Tablero contrachapado laminado: su alma está constituida por tablillas de chapa de grosor inferior a 7 mm, dispuestas de canto y encoladas todas ellas o al menos en su mayor parte.

Composición

Chapas de madera: láminas finas de madera que no sobrepasa los 7 mm de espesor. Si las láminas de madera se unen por sus cantos o testas se obtienen chapas compuestas. Para aplicaciones estructurales se clasifican principalmente por la presencia y frecuencia de nudos, y para aplicaciones decorativas por su estética.

Alma: en algunos casos, el tablero puede incorporar una capa central constituida por piezas de madera (listones, tablas, tablillas, etc) o láminas de madera adosadas y encoladas o no entre sí; por otros materiales derivados de la madera; por otros materiales en forma de lámina; o por una estructura alveolar.

Adhesivos: dependiendo de las características y de las propiedades requeridas se pueden utilizar adhesivos de Urea formol (para interiores) o Fenol formaldehído (para exteriores y estructurales).

Recubrimientos: se pueden utilizar chapas decorativas de madera, revestimientos plásticos, papel impregnado con resinas sintéticas, y pintura.

Aditivos: se incorporan durante su fabricación para mejorar algunas de sus propiedades ( productos ignífugos; productos insecticidas; productos fungicidas, resinas, etc.)

Aplicaciones

Decorativas:

- Fabricación de muebles (fondos, cajones)

- Revestimientos de paredes, techos y fachadas

Estructurales:

- Tablero de cubierta y diafragma

- Entrevigado y diafragma de forjados (rectos y curvos)

- Cerramiento y diafragma de muros

- Divisiones interiores, tabiques

- Alma de viguetas en doble T

- Encofrados

- Cajas de carga de camiones

- Suelos de autobuses

- Suelos especiales (velódromos, patinaje, etc.)

Tipos de Contrachapados

1.- Calidad de encolado

Se clasifican, principalmente, en función del ambiente en donde va a instalarse:

- en ambiente interior seco (clase encolado 1)

- en ambiente exterior cubierto (clase encolado 2)

- en ambiente exterior a la intemperie (clase encolado 3)

2.- Clasificación por otros aspectos y prestaciones

También se pueden clasificar en función de los siguientes aspectos:

- su composición: tablero de chapas, tablero de alma enlistonada, tablero contrachapado compuesto; tableros planos y tableros moldurados.

- estado de su superficie, su aptitud para el acabado o especificaciones especiales

- propiedades mecánicas: tableros estructurales

- resistencia al fuego: tableros ignífugos

- resistencia frente a organismos xilófagos: tableros tratados

- resistencia frente agentes meteorológicos: tableros impregnados con resinas

3.- Tableros contrachapados españoles

Las especies más habituales son las que se relacionan a continuación.

- Pino radiata

- Chopo

- Eucalipto

- Frondosas tropicales

Los fabricantes clasifican las chapas de acuerdo a criterios propios.

4.- Tableros contrachapados norteamericanos

Se clasifican según la durabilidad de su exposición y por sus aplicaciones (según la norma “Voluntary Product Standard PS 1-95").

- Durabilidad y exposición: interiores y exteriores

- Aplicaciones: marinos, decorativos, soportes de suelos, encofrados, estructurales, interiores encolados con adhesivos para exteriores, exteriores especiales y recubiertos.

Los tableros deben cumplir los requisitos relativos a: especies de madera; reparaciones que pueden incluir las chapas; calidad de las chapas; y espesor de las chapas.

5.- Tableros contrachapados finlandeses

En función de las especies de madera utilizadas se denominan:

- Abedul (Birch): chapas de abedul

- Combi: dos chapas de abedul en cara y contracara, y alma de chapas alternadas de pino y abedul.

- Combi Mirror: una chapa de abedul cara y contracara, y alma de chapas alternadas de pino y abedul.

- Gemela (Twin): una chapa de abedul cara ya contracara, y alma de chapas de pino.

- Coniferas (Conifer): chapas de pino o de picea.

Las chapas de madera se clasifican en dos grandes grupos, chapas de abedul y chapas de coníferas, que incluyen a su vez diferentes clases. Las clasificaciones se basan en la presencia de singularidades de la madera y de defectos de fabricación

Propiedades

Uniformidad de sus propiedades, poco peso y estabilidad dimensional. (es un material ideal para usos estructurales debido a la elevada resistencia, uniformidad de sus propiedades y a su poco peso)

- Densidad: depende de la/s especie/s utilizada/s.

- Estabilidad dimensional: muy estable, la tendencia a contraerse o dilatarse en la dirección perpendicular a la fibra está aminorada por las chapas adyacentes.

- Resistencia a la humedad: adecuada si se utilizan los de clase de encolado 3

- Conductividad térmica: mal conductor de la temperatura, al igual que la madera maciza. Los valores de la conductividad térmica (Kcal/mh ºC = W/ (m×K)) en función de la densidad del tablero (kg/m3) son: 0,09 para una densidad de 300, 0,13 para 500, 0,17 para 700 y 0,24 para 1000.

- Aislamiento acústico: depende del tipo de construcción y la forma en que se instalen. Para ruidos aéreos, los valores de los tableros de 30 mm de espesor se sitúan aproximadamente en 27 dbA.

- Reacción al fuego:

a) Clasificación española - Epirradiador: varía en función del espesor y especie, M-4 para espesores inferiores a 14 mm y M-3 si son superiores a 14 mm; con tratamientos ignifugantes M-1 y M-2.

b) Euroclases - SBI: espesores superiores a 10 mm con una densidad mínima de 400 kg/m3, D-s2, d0; DFL-s1.

c) con tratamientos ignifugantes mejoran sus prestaciones.

- Comportamiento frente a los agentes biológicos: en función de las clases de riesgo en que se encuentren pueden ser degradados por hongos xilófagos, insectos xilófagos de ciclo larvario e insectos xilófagos sociales (termitas). Su comportamiento se puede mejorar mediante su protección superficial, media o profunda. Ver bloque “Protección de la madera”.

- Conductividad eléctrica: en estado seco es prácticamente aislante.

- Acción de los rayos ultravioletas: la acción de la luz puede provocar la rotura de las fibras. Su comportamiento se puede mejorar mediante su protección superficial, media o profunda.

- Radios de curvatura: se pueden curvar. El factor limitante suele ser su espesor del tablero.

- Arranque de tornillos y clavos: excelentes propiedades.

- Propiedades estructurales: El fabricante ha de suministrar los valores característicos. Ver bloque “Construcción en Madera - Estructuras”.

Marcas de Calidad

Sello de Calidad AITIMs

Exige que el fabricante tenga implantado un control interno de fabricación. Incluye la realización de dos inspecciones anuales, en las que se recogen muestras para su ensayo y se comprueba la realización del control interno de fabricación.

Sello APA (American Plywood Association) y Sello COFI

El Sello de Calidad APA utiliza un esquema muy parecido al Sello de AITIM, pero en este caso la normativa que se aplica es la norteamericana.

Cerrar[X]