Ultimate materials

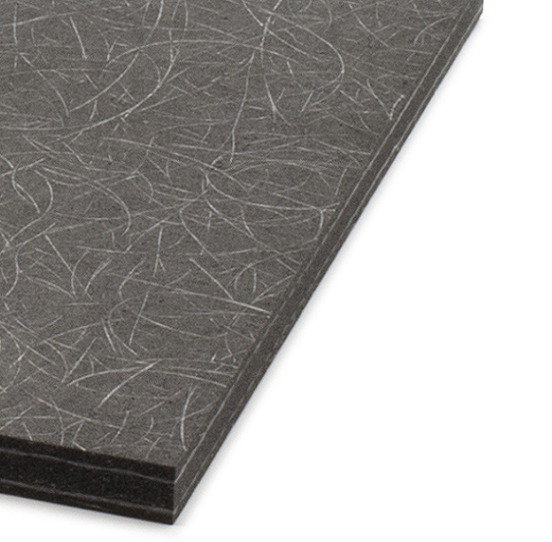

Since September 2019 Forest Trafic has incorporated a new range of products called Forest-THLite® manufactured with variable density polymer foam.

This new line of products represents the completion of the research of a replacement of birch plywood in projects that require a maximum resistance to biological agents and an extreme durability to outdoor environments. Furthermore, it can be a possibility for those uses needing lightweight but keeping high resistance and high modulus of elasticity.

Some general features for the cores of this new Product Forest-THLite:

- Good reaction to fire

- Does not harbor mold or fungus

- Very high resistance to corrosion

- Guaranteed rot free

- Self-extinguishing

- Good adhesive substrate

- Closed cell structure

- Lightness

- Low expansion and contraction ratio

- Lifetime buoyancy

- High mechanical resistance

- Completely impervious to water

- High impact strength

- High thermal insulation

- High acoustic insulation

- Resistant to contamination

The Forest-THLite® panel can be presented in multiple configurations with 5 different cores:

- Core. Manufactured with polymer foam. Available in a density range of 144 and 480 kg/m3 (depending on client requirements)

- Versatile. Manufactured with polymer foam and a light-density fiberglass lay-up. This material is a good choice in niche applications, such as floorings and ceilings. Available in a density range of 192 and 640 kg/m3 (depending on client requirements and upon thickness required).

- Tough-lite.Manufactured with polymer foam and a medium-density fiberglass lay-up. This material is acceptable for structural loading application. Available in a density range of 288 and 384 kg/m3 (depending on client requirements and upon thickness required).

- Tough.Manufactured with polymer foam and a high-density fiberglass lay-up. This material is acceptable for structural loading application. Available in a density range of 384 and 704 kg/m3 (depending on client requirements and upon thickness required).

- Supreme.Manufactured with polymer foam and an ultra-high-density fiberglass lay-up. This material is recommended for projects where the utmost load resistances are required. Available in a density range of 384 and 736 kg/m3 (depending on client requirements and upon thickness required).

All these materials can be coated with the usual laminates:

- Aluminum

- Polypropylene

- HPL

- PVC

- Natural wood veneer

- Phenolic compact

- Polyester

- Cork

- Rubber

- Linoleum

- Marble

- Plywood

There is a multitude of possibilities for achieving the physio-mechanical and/or esthetic requirements of our clients.

Since 01/09/2019, all this products are available for your pre-order.